This use of an O-ring is a variation of the static seal. Down to 008 ID.

What Are Static Seals Hot Topics

The OD of the ring should be about the same as the recess diameter.

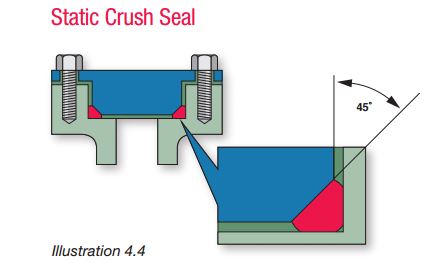

. Static Radial Seal Piston Seal Static Seals. The O-ring is crushed into a space having a cross-section different from that of a standard gland for example triangular. Crush seal Flange Seal Axial Seal In flange seal glands the two flanges are assembled with metal to metal contact.

This seal works by permanently deforming an o-ring into a small space typically triangular in cross section. A stretch greater than 5 on the O-ring ID. Over 2000 sizes of MicrOringTM seals from 039 ID.

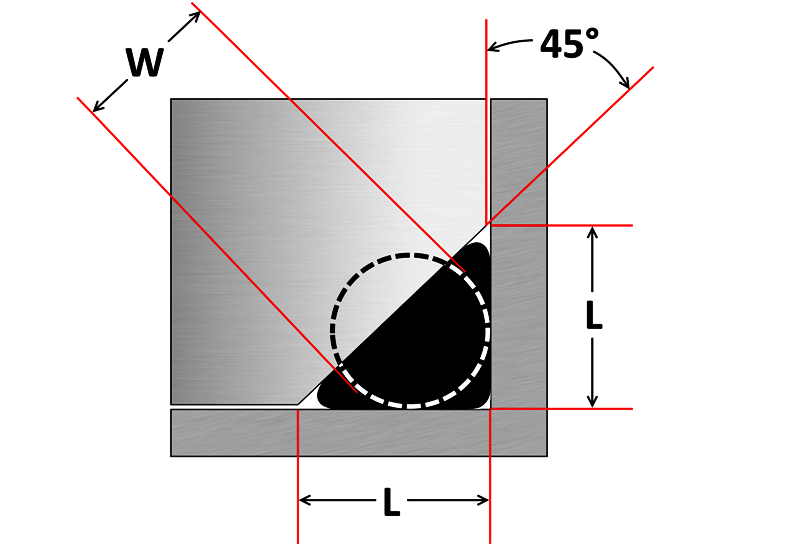

In a triangular groove the O-ring is pressed equally against three mating surfaces. The O-Ring is confi ned in a triangular recess made by machining a 45 degree angle on the male cover. Commonly called a crush seal design triangular groove designs have established a proven track record of success in numerous industries.

Contact Ace Seal regarding our static O-rings engineering guide today. In order to seal properly the o-ring has to deform in the application by being compressed and stretched in any number of ways. As important as the oring seal itself is the groove that the oring seats into.

Commonly called a crush seal design triangular groove designs have established a proven track record of success in numerous industries. Make sure that the material you choose will withstand the temperature of your system by going to this rubber temperature range chart. O-ring volume is usually 90-95.

Be it dynamic or static operation radial or axial loading vacuum or high pressure. Parker Hannifi n Corporation O-Ring Division. The largest selection of microminiature o-rings anywhere.

Male or Plug Seal design is based on the following factors refer to fig. The design of the groove where the o-ring sits plays a major role in how the o-ring performs its sealing role. Now follow the steps below to design your own o-ring seal and o-ring groove.

Traditionally an effective seal is created when a rubber seal element is pressed tightly between two mating compo- nents. More information including design criteria on O-ring drive belts and their application will be found in O-Ring Applications Section III. A Groove depth is the machined depth into one surface whereas a Gland depth consist of the groove depth plus diametrical clearance and is used to calculate seal compression.

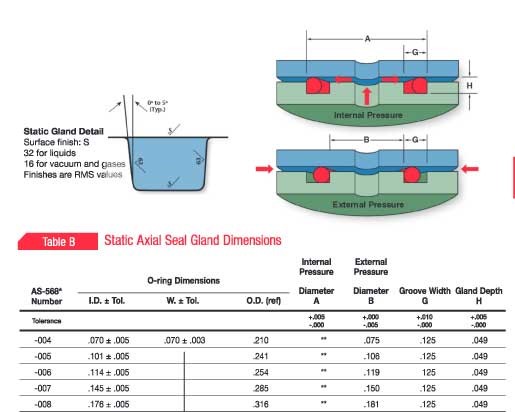

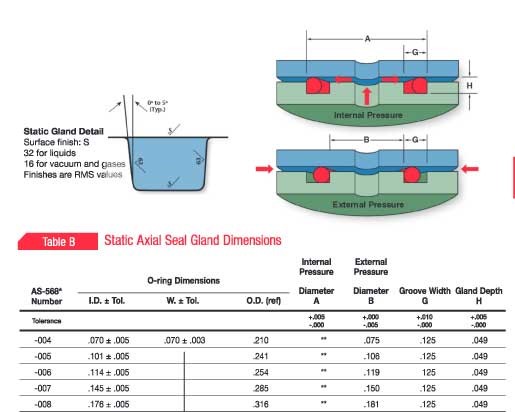

Design guidelines for O-Rings. DESIGN DIMENSIONS FOR O-RING INSTALLATION O-rings are normally used as seals in several ways and dimensions of the groove or gland will also vary with the cross section of the ring the type of operation and the amount of pressure used in the system. 2360 Palumbo Drive Lexington KY 40509 Phone.

Stretch should be less than 5 on the O-ring ID. The chart shows the recommended combined limits of clearance gap. This method does not need precise geometry and is typically used when looking to minimize machining cost or simplicity in low pressure applications.

Squeezed at an angle to the O-rings axis crush seals are used in such simple applications as the one depicted in Illustration 44. Groove depth must be smaller than the O-ring CS. Now follow the steps below to design your own o-ring seal and o-ring groove.

Most o-rings are designed to operate at pressures up to 1500 psi. Microminiature composite seals and custom-engineered microminiature. The following information is a guide for oring groove dimensions for both static and reciprocating.

859 269-2351 Fax. Female or Tube - the O-ring groove is located in the housing or cylinder and a tube is installed through the O-ring lD. Gland Depth E as shown in the.

Designing the parts of an application where o-rings will be applied is broadly termed o-ring groove design. Choose your rubber properties by going to our O-ring Material Guide section. A crush seal is a unique style of static seal.

Bore Diameter A Plug Diameter H Groove Diameter B Groove Width F as shown in the dimension tables. In these applications a triangular-shaped O-ring groove may be the solution to the design dilemma. Groove design guide for static o-ring face seals provides default recommendations on width depth diameter and more for basic applications.

Application Engineering United States. These dimensions will also be different if the O-ring is sealing a liquid which has a low volume. Lead Times As Low As 3 Weeks.

O-ring face seals are used in a variety of applications including bolted flanges or removable lids. The same sealing principle applies to crush type seals used in recesses of straight thread tubing bosses. The O-Ring is confi ned in a triangular recess made by machining a 45 degree.

Is not recommended because it can lead to a loss of seal compression. The parameter dashboard in the Results section will immediately show you if the selected O-ring size is suitable for your application. Traditionally an effective seal is created when a rubber seal element is.

So in fact there is no remarkable gap and no. The groove must be designed to accommodate not just the oring size but also its intended usage. In crush seal applications the O-ring is completely confined and pressure deformed crushed within a triangular gland made by machining a 45 angle on the male cover.

Application Engineering Europe. While it is an effective seal the O-ring is permanently deformed and therefore generally considered non-reusable. Static Crush Seal Gland Dimensions.

At higher pressures the material must have enough strength to resist extruding into the clearance gap. This type of crush seal is used where cost and ease of machining are im- portant. O-ring may be asked to seal two leak paths between mating parts.

O-ring Gland Design Dovetail seal Also here there is a metal to metal contact as long as the con-struction will not deform under system pressure. A MicrOringTM seal is any o-ring that measures less than 1 mm in either inside diameter ID or cross section CS. An O-ring seal is used to prevent the loss of a fl uid or gas.

Ad Specializing In Custom Sized Colored Color Coded O-Rings. Top-Tier Quality Speedy Delivery At Cut-Rate Prices. Request A Quote Today.

Applications Technology Sealing Elastomers In The Semiconductor Industry Are Used In Hundreds Of Applications Unique Environments Such As Vacuum And Plasma And Demanding Requirements For Contamination Place Great Importance On The

O Ring Groove Design Sealing Australia

Triangular O Ring Grooves Mechanical Seal Engineering Eng Tips

How To Design An O Ring Groove Vizeng

O Ring Groove Design Global O Ring And Seal

The Apple Rubber Seal Design Guide Turns 25 Official Apple Rubber Blog

0 comments

Post a Comment